Silvios Aronia Farm

Pick Your Own Aronia Berries

Starts Sept 1st, 2023

Ends Late October

Aronia Berry Picking season Started early last year.

We had a great & lucsious crop in 2022.

Lets hope for the same in 2023.

It’s Great fun for the whole family.

Note: No dogs allowed in the fields & there are no washroom facilities at the farm.

September & October is a great time for you to visit our farm in Port Perry Ontario.

Only 30 minutes north of Hwy 401, Exit 410 Brock St, Whitby Ontario

FEATURE SECTION

Silvio’s Farm featured on The Standard’s Health & Fitness section

Local Aronia berries loaded with antioxidant advantages…

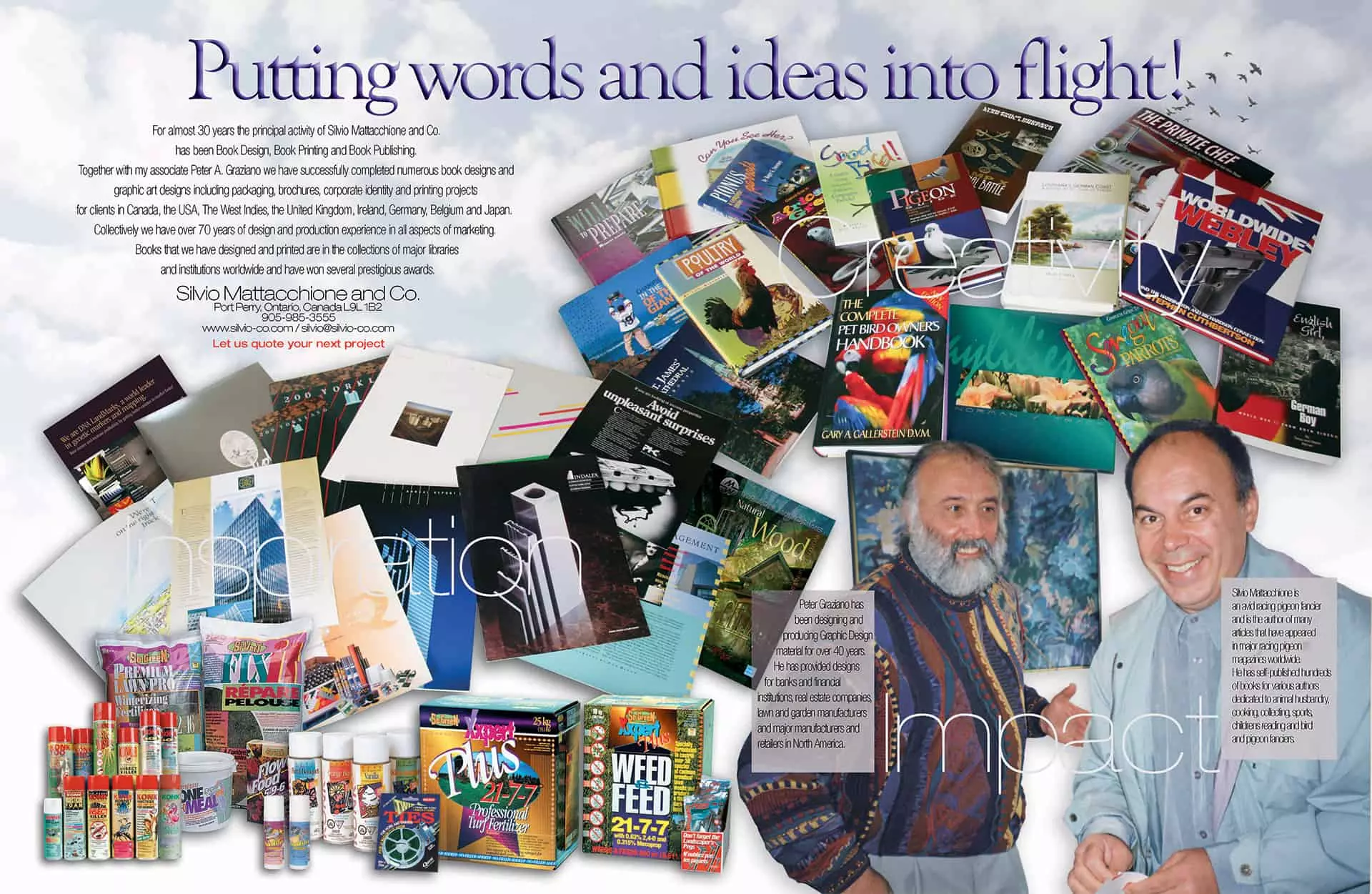

Book Store

As publishers of fine books, we have accumulated a collection of books over the years that we are now making available in our online book store.

Many books are in the category of pet birds and other animals, which include books about parrots, pigeons, racing pigeons, poultry, waterfowl, peafowl, farm animals, rabbits, dogs, hunting, guns, skunks, fish, snakes, and other small animals.

You will also find some Very Rare used Pigeon Books in our store.

Some of our books that have been in storage or on our shelves for years may have some defects. These books even though they have never been sold or read, we will deem them as a used book in our store. The condition of the book will be listed in the description.